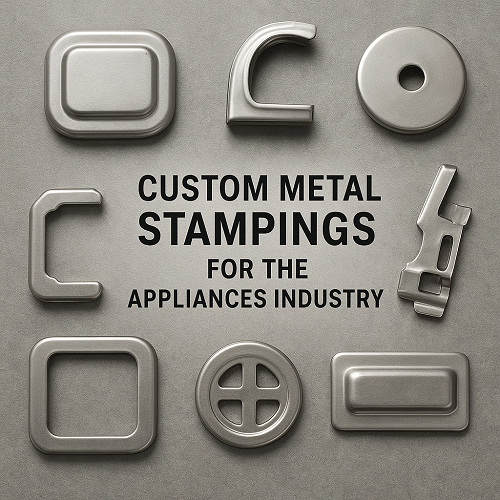

The appliances industry demands precision, durability, and cost-efficiency at every stage of production. From household devices such as refrigerators, dishwashers, and washing machines to commercial-grade cooking and HVAC systems, custom metal stampings play a pivotal role in ensuring both mechanical reliability and aesthetic appeal. Metal stamping, as a manufacturing process, provides the accuracy, repeatability, and scalability necessary to produce millions of high-quality components for appliance manufacturers worldwide.

Metal stamping refers to the process of transforming flat sheet metal into complex shapes using dies and high-tonnage presses. Depending on the part’s design, multiple operations such as blanking, piercing, bending, forming, deep drawing, embossing, and coining may be performed in a single progressive die or across multiple stages.

Because appliance components often serve both functional (mechanical, electrical, or thermal) and visual purposes, stamping processes must achieve tight tolerances and flawless surface finishes.

| Material | Characteristics | Common Applications |

| Cold-Rolled Steel (CRS) | Excellent dimensional tolerance; suitable for post-plating | Brackets, frames, chassis |

| Stainless Steel (304, 316, 430) | Corrosion-resistant, durable, high aesthetic appeal | Refrigerator doors, cooktop components |

| Aluminum (3003, 5052, 6061) | Lightweight, corrosion-resistant, thermally conductive | Heat exchangers, control panels |

| Copper & Brass | Excellent electrical conductivity; good formability | Electrical contacts, switches |

| Galvanized Steel (G90, G60) | Zinc coating for corrosion protection | Internal supports, washing machine panels |

Material selection often depends on whether the part will be visible, exposed to heat, moisture, or electrical current, or integrated into moving assemblies.

A coil of metal passes through a series of die stations within a single press. Each station performs a specific operation, culminating in a finished part at the end of the line.

Each part is transferred from one die station to the next by mechanical fingers or automation systems.

Used to create hollow or cylindrical components with significant depth relative to diameter — such as cups, basins, or enclosures.

Provides smooth, precise edges and minimal burr formation, which is crucial for aesthetic panels or components that require tight-fitting assembly.

Tooling is the backbone of any stamping process. In appliance manufacturing, progressive and compound dies are designed using CAD/CAM software and verified through finite element analysis (FEA) to simulate stress distribution, springback, and forming limits.

High-quality tool steels (D2, A2, M2, carbide inserts) are typically used for extended die life, especially in high-volume production runs.

Because appliance assemblies often involve precision fits between stamped, molded, and machined parts, tight dimensional tolerances are non-negotiable. Typical tolerances range from ±0.05 mm to ±0.25 mm, depending on part size and function.

For visible appliance components, cosmetic inspection (checking for scratches, dents, or uniform finishes) is equally important.

Modern appliance manufacturers increasingly rely on automated stamping cells integrated with robotic material handling, vision systems, and real-time data collection.

These improvements not only minimize environmental impact but also drive long-term cost savings.

Custom metal stampings form the structural and functional foundation of nearly every appliance on the market today. Through a combination of advanced materials engineering, high-precision tooling, and automated manufacturing systems, appliance OEMs can achieve consistent quality, lower production costs, and faster time to market.