Metal stamped parts play a foundational role in modern furniture manufacturing, providing the structural stability, functional reliability, and aesthetic refinement required across residential, commercial, and industrial environments. By converting sheet metal into precise, repeatable components, stamping enables manufacturers to achieve tight tolerances, consistent quality, and large-scale production efficiency. Our metal-stamped furniture components are engineered to support demanding usage conditions while enhancing product durability, appearance, and overall performance.

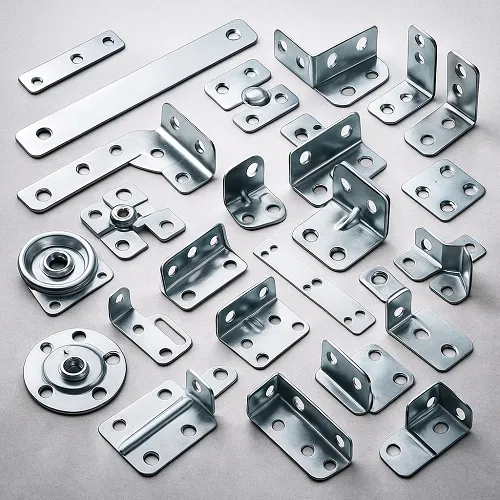

Metal stamped parts are essential for critical load-bearing, structural, and connection functions in furniture assemblies. These components are commonly used in hinges, brackets, support frames, slide rails, mounting plates, angle reinforcements, and decorative metal trims. Their primary function is to ensure secure attachment between furniture elements, maintain mechanical integrity under repetitive stress, and provide smooth movement for adjustable or foldable mechanisms. Beyond structural roles, metal stamping also produces visually refined surfaces used in modern minimalist designs, industrial-style furniture, and architectural hardware. From office desks and hotel fixtures to cabinets, beds, and seating systems, stamped metal parts contribute to long-term stability and ergonomic performance.

Our metal stamped furniture components are designed with engineering precision and manufactured to consistently meet performance expectations. They offer high dimensional accuracy, excellent abrasion resistance, exceptional load-bearing capability, and strong resistance to deformation, even under continuous mechanical stress. Advanced stamping techniques—such as progressive dies, deep drawing, and multi-stage forming—allow for complex shapes, lightweight designs, and optimized material utilization. Surface treatments like powder coating, zinc plating, electropolishing, and anodizing further enhance corrosion resistance and extend service life. Additionally, every part can be customized in terms of geometry, thickness, hardness, and finishing to align perfectly with the furniture manufacturer’s design specifications.

Metal stamped parts for furniture can be produced from a wide range of materials, including cold-rolled steel, stainless steel (304/316), aluminum alloys, brass, and high-strength galvanized steel. Typical thickness options range from 0.3 mm to 5.0 mm depending on structural requirements. Dimensional tolerances are kept within ±0.05 mm for high-precision assemblies, ensuring seamless compatibility with mating components. Our stamping equipment supports small to large formats, part sizes from micro-components to large brackets, and manufacturing volumes from prototype batches to mass production. Optional laser cutting and CNC post-processing can be integrated to achieve complex geometries and fine detail work.

To maximize performance, engineers and furniture manufacturers should select stamped metal parts based on load conditions, environmental exposure, and assembly methods. Components should be installed following recommended torque specifications, positioning guidelines, and fastening instructions to ensure structural stability. When used in moving mechanisms, such as drawer slides or foldable hinges, appropriate lubrication and periodic inspections help maintain long-term functionality. For outdoor or moisture-prone environments, choosing corrosion-resistant materials or treated surfaces is essential to prevent degradation. Our team provides technical drawings, sample testing, and product compatibility guidance to support smooth integration into furniture production lines.

Metal stamped furniture components are widely used in home furniture, office furniture, commercial interiors, hospitality fixtures, medical furnishings, educational equipment, retail shelving, industrial workstations, and architectural hardware. Any sector requiring robust mechanical support, repeated movement, or aesthetic metal accents relies on precision-stamped parts to ensure product durability and user comfort. The versatility of stamping technology allows these components to be customized for traditional craftsmanship, modern minimalist designs, or heavy-duty industrial structures.

Our stamped metal parts are engineered for furniture manufacturers, OEM/ODM producers, interior fixture suppliers, hardware distributors, and industrial design companies seeking premium-quality components. We also support architectural contractors, office system integrators, and brand owners who require specialized metal parts for custom furniture lines. Whether the need is for large-scale production, small-batch prototyping, or fully customized solutions, we provide reliable, cost-effective, and precision-engineered components tailored to each customer’s unique specifications.