metal stamped parts have become integral to modern furniture manufacturing, offering a blend of durability, consistency, and cost-efficiency. From structural components to decorative accents, these parts support both form and function.

1. Structural Components for Strength and Stability

Metal stamped parts are widely used in structural applications, where strength, and consistency are crucial.

- Chair and Table Frames: Stamped steel brackets and braces reinforce the structure, enhancing load-bearing capacity.

- Bed Frames and Supports: parts help assemble bed slats and support beams, ensuring durability and safety.

- Cabinet and Shelf Mounts: Brackets and backplates are stamped to exact specifications for easy and secure installation.

2. Hardware for Movement and Functionality

Moving parts in furniture require accuracy to ensure smooth operation, and metal stamped parts provide the perfect solution.

- Drawer Slides and Glides: Metal channels and tracks are stamped for a perfect fit, ensuring seamless opening and closing.

- Hinges and Pivot Joints: Hinges with stamped components offer uniform performance, critical in doors and foldable furniture.

- Adjustable Mechanisms: Height adjusters, recliner supports, and swivel mechanisms often use metal stamped levers and plates.

3. Decorative Elements and Aesthetic Enhancements

While functionality is key, metal stamped parts also contribute to the visual appeal of furniture.

- Ornamental Trim and Panels: Stamped decorative patterns can be used on drawer fronts, cabinet faces, or chair backs.

- Logo Plates and Name Tags: stamping enables branding elements to be created with sharp, consistent detail.

- Custom Design Accents: Intricate metal filigree or accent pieces can be economically mass-produced through stamping.

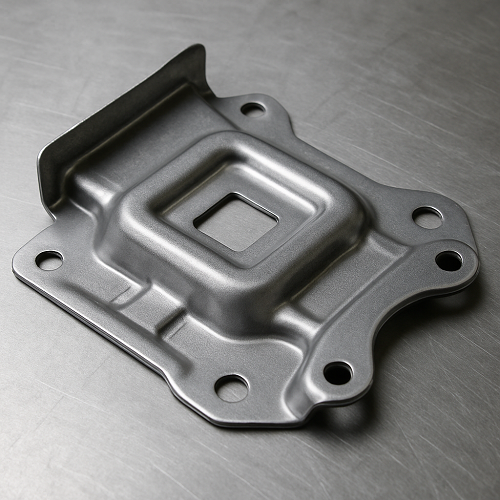

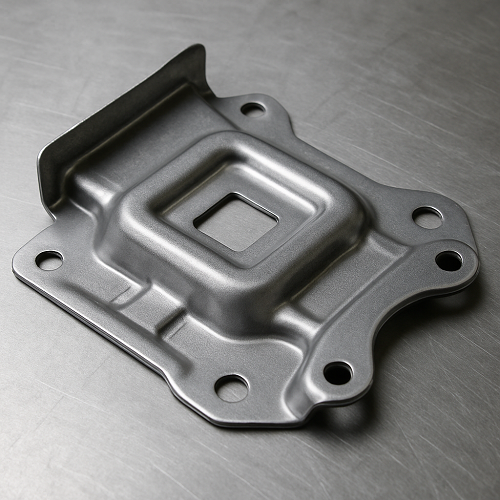

4. Fasteners and Assembly Aids

Ease of assembly is a major consideration in furniture design, and metal stamped parts play a central role here.

- Brackets and Corner Plates: Used to connect and reinforce corners in flat-pack furniture.

- Mounting Plates: Provide secure bases for attaching components like legs or accessories.

- Clip Systems: Spring clips and snap-in retainers, often made via stamping, speed up assembly processes.

5. Cost Efficiency in Mass Production

Furniture manufacturers prioritize both quality and budget.

Metal stamped parts offer the following economic benefits:

- Low-Cost Production at High Volumes: Once dies are created, stamping is an efficient and low-waste process.

- Consistent Quality: Every part produced is nearly identical, reducing quality control issues.

- Minimal Secondary Processing: Many stamped parts require little to no post-production finishing.

6. Customization and Innovation Opportunities

The flexibility of stamping allows for customization, making metal stamped parts ideal for modern furniture trends.

- Custom Tooling for Unique Designs: Specialized dies can be created to produce unique parts tailored to specific furniture lines.

- Integration with Other Materials: Metal parts can be combined with wood, plastic, or glass to create hybrid designs.

- Modular Systems: Components designed for modular furniture benefit from the and repeatability of stamped metal.

7. Sustainable and Eco-Friendly Options

Sustainability is increasingly important in furniture production, and metal stamped parts support green manufacturing practices.

- Recyclable Materials: Most stamped parts are made from steel or aluminum, which are fully recyclable.

- Efficient Use of Material: Stamping maximizes material usage, reducing waste.

- Durability Equals Longevity: High-quality metal parts extend furniture lifespan, reducing environmental impact.