In the world of industrial design, construction, and manufacturing, metal assembling accessories play a pivotal role in ensuring the durability, precision, and versatility of structures. These accessories are not just secondary tools—they are the foundation of solid assemblies, enabling professionals across industries to build with confidence and efficiency.

What Are Metal Assembling Accessories?

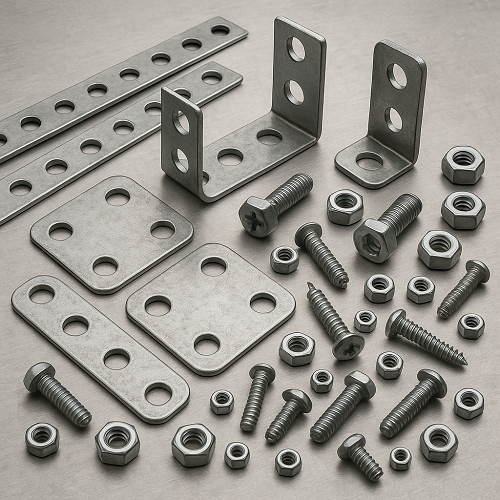

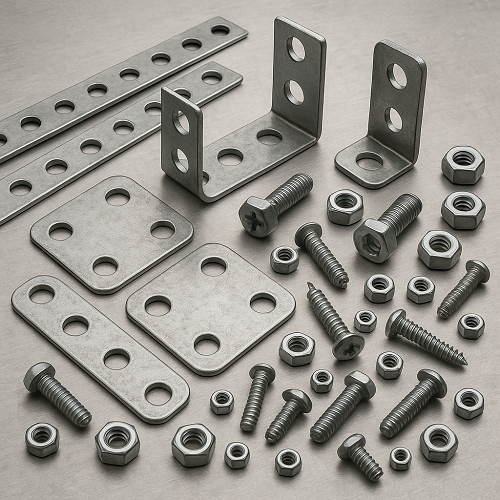

Metal assembling accessories include a broad range of components used to join, reinforce, or complete metal structures.

These accessories encompass:

- Bolts and Screws: Fasteners designed to provide strong, often removable connections.

- Nuts and Washers: Used in conjunction with bolts to secure metal parts firmly.

- Brackets and Plates: Provide structural support and stability at junctions.

- Clamps and Connectors: Allow for flexible or semi-permanent joining of metal elements.

- Hinges, Latches, and Locks: Facilitate movement and security in metal frameworks.

- Rivets and Welding Inserts: Offer permanent and high-strength bonding solutions.

Each accessory is designed for specific types of applications, ranging from light-duty furniture assembly to heavy-duty steel construction.

- Enhanced Durability and Strength: High-quality metal accessories are made from robust materials like stainless steel, aluminum, and zinc alloys, ensuring longevity and resistance to corrosion and wear.

- Precision and Customization: Modern assembling components are manufactured to exacting standards, allowing for precise alignments and fits, which is critical in engineering and architectural projects.

- Ease of Installation and Maintenance: Most accessories are designed for user-friendly assembly and disassembly, reducing labor costs and making maintenance more manageable.

- Flexibility and Modularity: Accessories enable modular design approaches, allowing parts to be easily replaced, upgraded, or reconfigured.

Applications Across Industries

- Construction: Used in metal framing, roofing, and façade systems.

- Automotive and Aerospace: Critical in chassis assembly, bodywork, and mechanical systems.

- Furniture Manufacturing: Enable the creation of modular, durable, and aesthetically pleasing designs.

- Electronics and Appliances: Support the internal framework and housing components.

- DIY Projects and Home Improvement: Widely available for custom builds and renovations.

Choosing the Right Accessories

When selecting metal assembling accessories, consider:

- Load Requirements: Ensure the accessory can withstand the intended weight or pressure.

- Environmental Conditions: Choose corrosion-resistant materials for outdoor or marine applications.

- Compatibility: Match accessories to the type and gauge of metal being used.

- Regulatory Compliance: In critical applications, components should meet industry standards such as ISO, DIN, or ASTM.