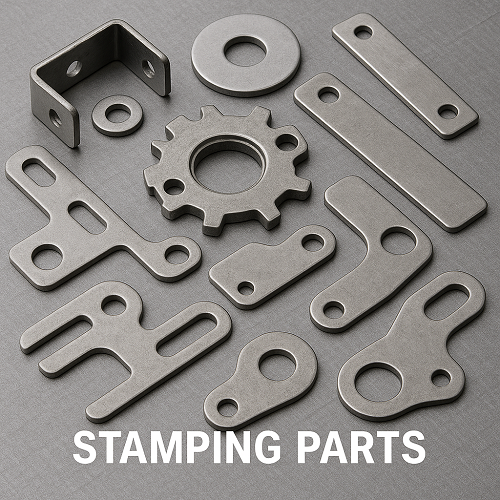

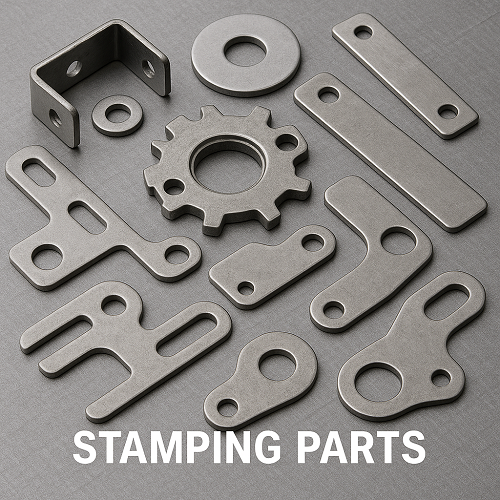

In the vast world of manufacturing, precision and efficiency are paramount. Among the myriad processes that contribute to high-quality production, stamping stands out as one of the most widely used and essential methods. Stamping parts—components formed through the stamping process—play a foundational role in numerous industries, including automotive, aerospace, electronics, and home appliances.

What Are Stamping Parts?

Stamping parts are metal components produced by placing flat sheet metal into a stamping press where a tool and die surface form the metal into the desired shape. This process may include several techniques such as punching, bending, embossing, blanking, and coining, depending on the complexity and function of the part.

Materials commonly used include aluminum, stainless steel, copper, and various alloys, chosen based on the required properties such as strength, conductivity, or corrosion resistance.

Advantages of Stamping Parts

- High Precision and Consistency: Once the die is created, the stamping process can produce thousands or even millions of identical parts with extremely tight tolerances.

- Cost-Effectiveness for High Volumes: The initial investment in tooling is offset by low per-unit costs for large-scale production runs.

- Speed of Production: Stamping machines can produce parts rapidly, reducing lead times and boosting throughput.

- Versatility in Design: Complex geometries can be achieved through progressive dies and compound stamping, allowing engineers to create intricate parts without the need for additional machining.

Applications Across Industries

- Automotive Industry: Stamping parts are used extensively in vehicle bodies, engine components, brackets, and structural elements. High-strength stamped parts contribute to lighter, safer vehicles.

- Electronics: Stamped parts such as connectors, terminals, and shielding components are vital in the assembly of consumer electronics and industrial devices.

- Aerospace: Lightweight and durable stamped parts help improve fuel efficiency and structural integrity in aircraft.

- Medical Devices: Precision is critical in the medical field, and stamping provides reliable components for instruments and equipment.

Innovations in Stamping Technology

With the rise of Industry 4.0, stamping technology is evolving rapidly. Key innovations include:

- Automation and Robotics: Automated material handling and robotic arms enhance speed and reduce manual labor.

- CNC and CAD Integration: Computer-aided design (CAD) and CNC-controlled presses enable more complex designs and faster prototyping.

- High-Speed Stamping: Newer presses can operate at significantly higher speeds, boosting productivity without compromising quality.

- Environmentally Friendly Practices: Modern stamping operations aim to minimize waste through efficient material usage and recycling initiatives.

Stamping parts are a cornerstone of modern manufacturing, enabling the creation of complex, high-precision components at scale. As industries push for lighter, more efficient, and more cost-effective products, the role of stamping in delivering reliable and innovative solutions will only continue to grow. With ongoing advancements in technology, stamping remains a dynamic and indispensable force in global production.