In today's fast-paced industrial environment, efficiency, and consistency are more important than ever. As manufacturers strive to meet increasing demands and maintain high quality standards, stamped parts have become critical components in a wide range of industries, including automotive, electronics, and aerospace.

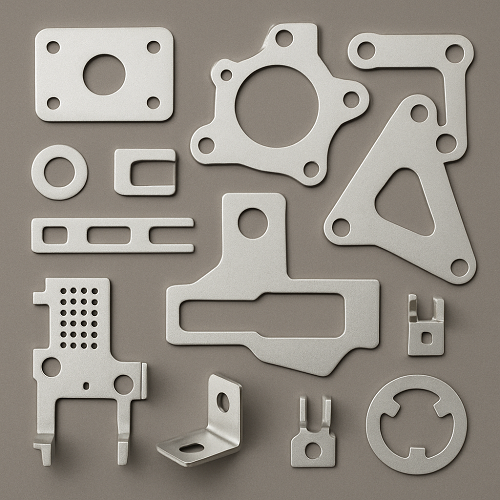

stamped parts are metal parts produced using stamping processes. These processes involve feeding flat metal into a stamping press and then using a die to form it into the desired shape. The resulting part has precise specifications, tight tolerances, and excellent repeatability.

With digital design tools, real-time quality monitoring, and the integration of advanced materials, stamping technology is evolving to meet the challenges of the next generation of manufacturing. As industries move toward miniaturization and high performance, the demand for stamped parts will continue to grow.

stamped parts are the backbone of modern manufacturing, offering high reliability, low cost, and excellent performance. Organizations that invest in stamping technology are better positioned to innovate, compete, and excel in a rapidly evolving industrial environment.