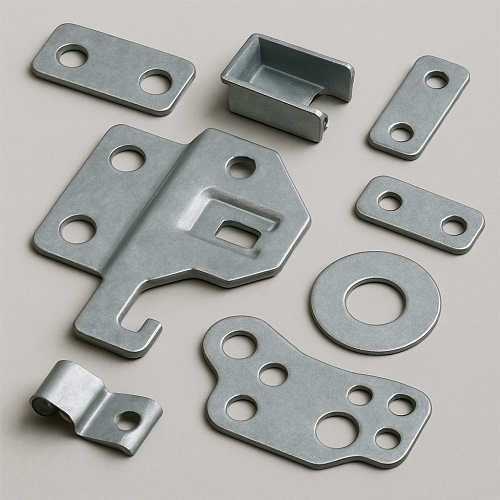

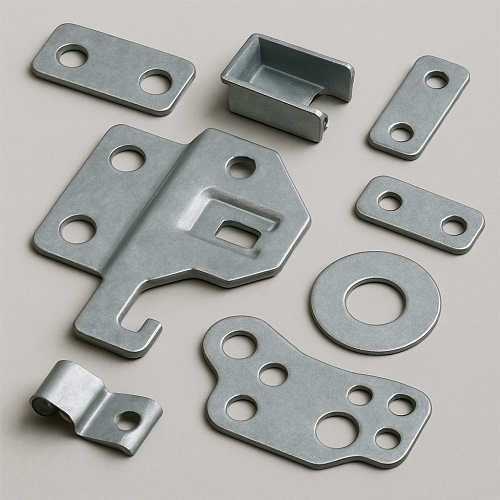

Often unnoticeable but vital, Stamped Parts are fundamental components in industries such as automotive, aerospace, electronics, and appliances. As the manufacturing industry's demand for more efficient, lightweight materials and complex geometries continues to grow, metal stamping has become a cornerstone of production, enabling precision, repeatability, and cost-effectiveness at scale.

What are Stamped Parts?

Stamped Parts are metal parts formed through a stamping or pressing process that uses a die and press to form a flat sheet of metal into a specific shape. This method can perform a series of operations, such as dropping, punching, bending, embossing, and flanging - usually in one pass or through a series of progressive stages.

Advantages of Using Stamped Parts

- Efficiency at Scale: Once the tooling is designed and set up, the stamping process allows for rapid, high-volume production with minimal deviation. This repeatability is essential for mass production.

- Cost Effectiveness: Compared to machining or casting, Stamped Parts reduces material waste and labor costs, especially for high volume production.

- Complexity and Versatility: Advanced stamping technologies, including progressive die stamping and deep drawing, can produce complex parts to tight tolerances.

- Material Versatility: Stamped Parts can be made from steel, aluminum, brass, copper, and specialty alloys, each selected for its unique properties for different applications.

Cross-industry applications

- Automotive: Stamped Parts include brackets, chassis components, panels, and connectors that are critical to structural integrity and performance.

- Electronics: Heat sinks, shielding components, and battery terminals rely on precision stamping for functionality and compact design.

- Household Appliances: Stamped Parts metal parts form the structural framework and internal mechanisms of everyday household appliances.

- Aerospace & Defense: Stamped Parts are lightweight and strong to meet the demanding specifications required for flight and military systems.

Future Prospects: Stamping Innovation

As technology advances, stamping processes are evolving with automation, computer-aided design (CAD), and high-speed progressive die systems. The integration of robotics and real-time quality control is transforming stamping facilities into intelligent manufacturing centers.