Metal stamped parts have become indispensable components in industries such as automotive, aerospace, electronics, and medical devices. These precision-engineered components are manufactured using a process known as metal stamping, which employs presses and dies to form flat metal sheets into specific shapes. With advancements in technology, metal stamping has evolved into an efficient, cost-effective, and versatile method for producing complex components that meet stringent quality standards.

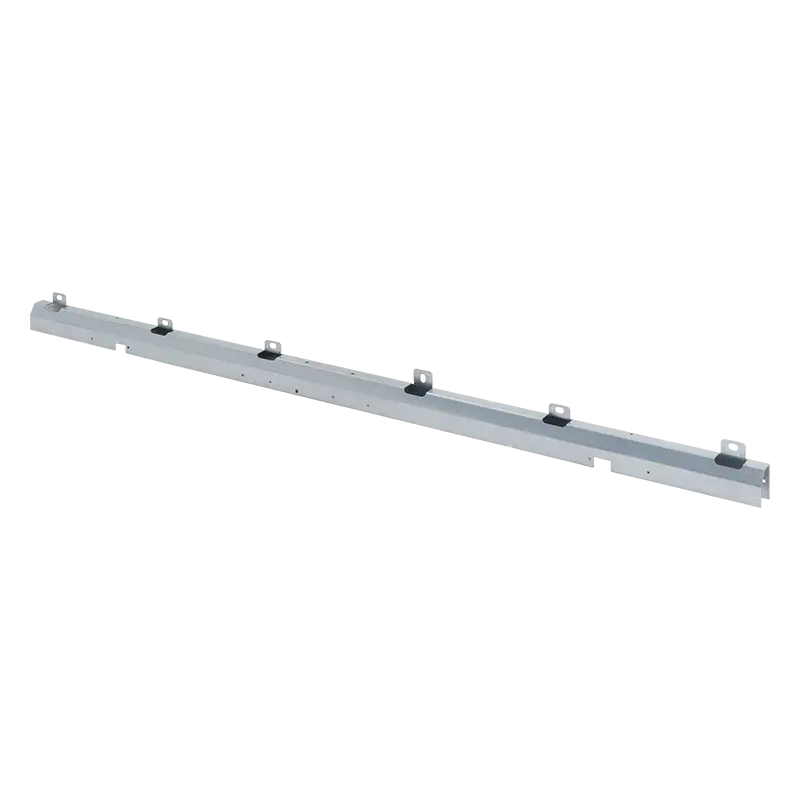

Metal stamped parts are formed by pressing, punching, bending, or embossing metal sheets into predetermined shapes. This process relies on specialized stamping presses and custom-designed dies to ensure consistency and precision. Commonly used materials include stainless steel, aluminum, copper, brass, and carbon steel, with each material selected based on the mechanical properties required for the application.

From miniature connectors in smartphones to structural components in aircraft, metal stamped parts are ubiquitous. Their versatility stems from their ability to mass-produce simple flat shapes and complex three-dimensional geometries with minimal material waste.

Metal stamping involves multiple steps, typically integrated into a single process to enhance efficiency.

High-speed progressive stamping machines can produce hundreds or even thousands of parts per hour, making them ideal for large-scale production.

With the rise of Industry 4.0 and advanced manufacturing technologies, metal stamping technology continues to evolve. Computer-aided design (CAD) and simulation software enable engineers to optimize part designs before production begins. Automated stamping presses equipped with sensors and real-time data monitoring can enhance efficiency and reduce defects. Additionally, hybrid stamping technology—combining stamping with laser cutting or 3D forming—opens new possibilities for producing complex, lightweight, and high-strength components.

Metal stamped parts are the unsung heroes of modern engineering, delivering precise, durable, and efficient products across countless applications. As industries demand higher performance and lighter materials, metal stamping technology continues to innovate, offering cutting-edge solutions to meet evolving design and production requirements. With ongoing advancements in tooling, automation, and digitalization, the future of metal stamping promises to deliver enhanced production capabilities and cost advantages for manufacturers worldwide.