In the ever-evolving landscape of industrial production, metal stamping forming stands out as a cornerstone technology, shaping the way components are manufactured across a multitude of sectors. From automotive body panels to intricate electronic connectors, this process enables mass production with unmatched precision, speed, and cost-efficiency.

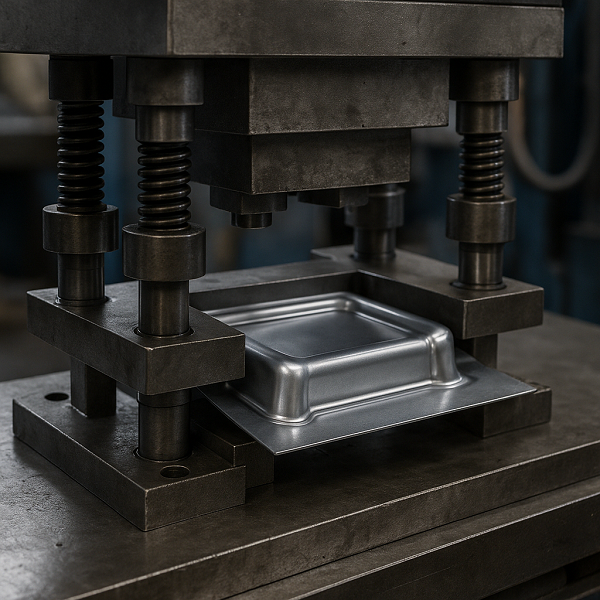

Metal stamping forming is a manufacturing process that transforms flat metal sheets into desired shapes through the use of dies and presses. The process involves a series of operations—such as punching, bending, embossing, and coining—carried out under high pressure to produce complex geometries with high repeatability.

Recent advancements have introduced computer-aided design (CAD) and finite element analysis (FEA) to simulate the forming process before tooling is built, reducing lead times and minimizing errors. Additionally, servo-driven presses allow more control over stroke and pressure, improving part quality and enabling more complex shapes.

As industries aim to reduce environmental impact, metal stamping forming supports sustainability by minimizing material waste through precise design and efficient nesting. Recyclable metals like aluminum are commonly used, and modern presses are increasingly energy-efficient.