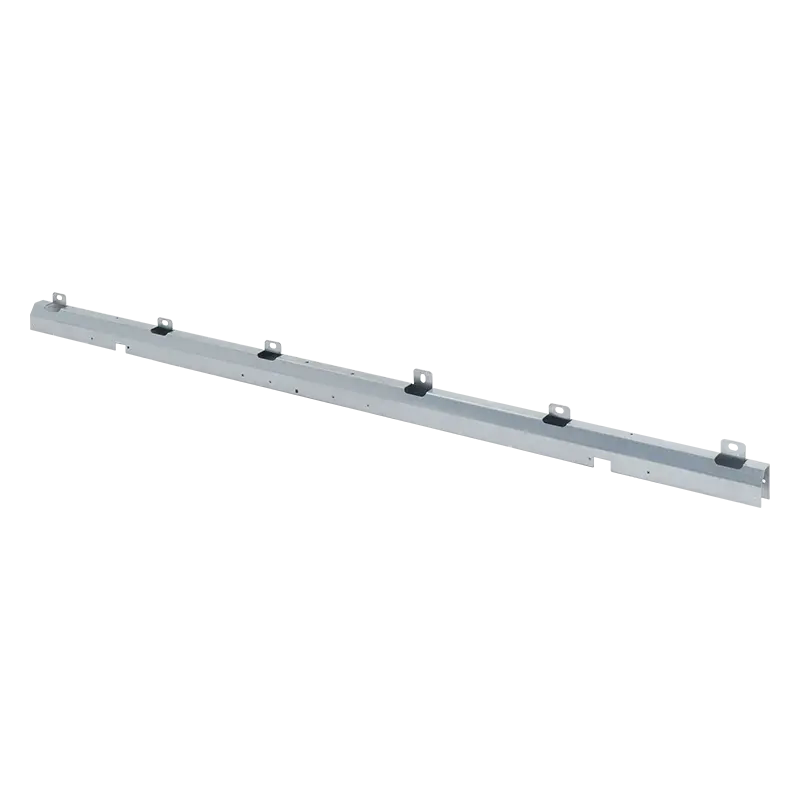

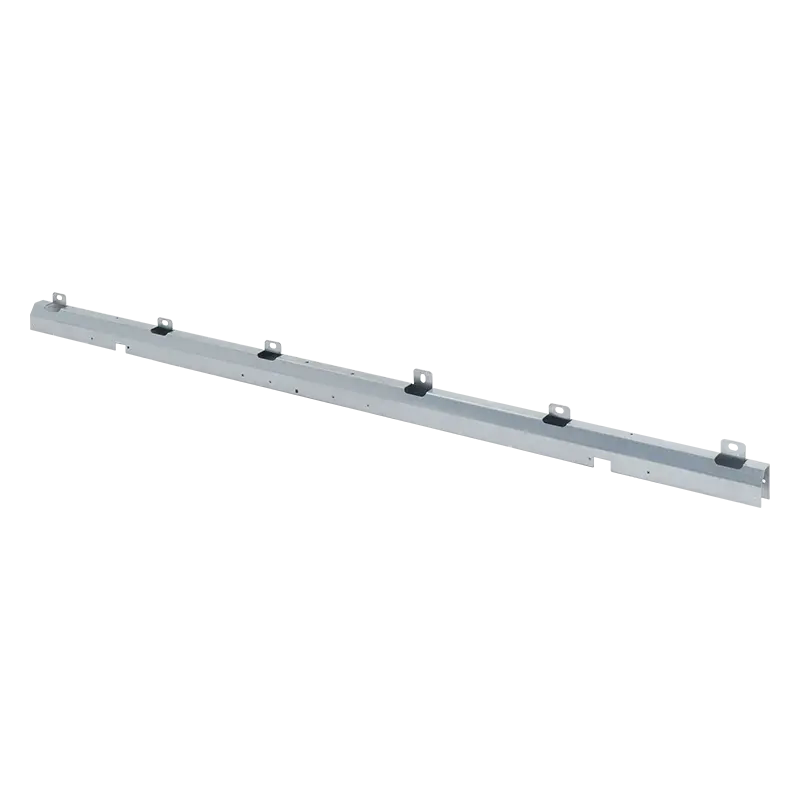

Metal stamped parts are essential components in a wide range of industries, offering precision, efficiency, and cost-effectiveness.

What is Metal Stamping?

Metal stamping is a manufacturing process that uses dies and high-pressure presses to shape flat metal sheets into specific forms. The result is what we call metal stamped components—custom parts that match exact design specifications.

The process typically involves blanking, punching, bending, and coining.

A wide variety of metals can be used, including aluminum, copper, steel, and stainless steel.

It’s a high-speed and high-precision technique suitable for large production runs.

Advantages of Using Metal Stamped Components

Utilizing metal stamped parts provides significant benefits in both design and production phases.

Here are some key advantages:

- Precision Engineering: Metal stamping produces parts with tight tolerances and consistent quality, ideal for complex designs.

- High Production Efficiency: The process is fast and scalable, making it cost-effective for high-volume manufacturing.

- Material Versatility: A wide range of metals can be stamped, accommodating different strength, weight, and corrosion-resistance needs.

- Reduced Waste: The efficiency of metal stamping minimizes material waste, making it a more sustainable option.

- Lower Labor Costs: Automation and high-speed machinery reduce the need for manual labor, helping to lower operational costs.

- Types of Metal Stamping Processes: There are various techniques used in creating metal stamped parts, each with its specific strengths:

- Progressive Die Stamping: A strip of metal moves through a series of stations where different operations are performed. It’s efficient for producing complex parts quickly.

- Transfer Die Stamping: The metal piece is moved from station to station by a mechanical transport system, suitable for larger, more complex shapes.

- Deep Draw Stamping: This method forms parts with deep cavities, like automotive housings or kitchen sinks, using a combination of tensile and compressive forces.

- Four-Slide Stamping: Ideal for intricate parts with multiple bends, this process allows for complex forming in a single machine setup.

- Fine Blanking: This high-precision technique is used when smooth edges and exact dimensions are critical, often seen in automotive and electronics components.

Common Applications of Metal Stamped Parts

Metal stamped components are found in nearly every sector. Their versatility and cost-effectiveness make them a go-to solution for many industries:

- Automotive: Brackets, clips, heat shields, and structural components.

- Electronics: Connectors, terminals, and shielding elements.

- Medical Devices: Surgical instruments and precision enclosures.

- Aerospace: Lightweight structural parts and engine components.

- Consumer Products: Appliance housings, tools, and hardware.

Choosing the Right Metal Stamped Parts for Your Project

Selecting the ideal metal stamped parts depends on several key considerations:

- Material Selection: Choose based on required strength, weight, conductivity, and corrosion resistance.

- Design Complexity: Evaluate whether your design is suitable for stamping or requires custom tooling.

- Volume Requirements: High-volume projects benefit most from the efficiency of metal stamping.

- Tolerances and Specifications: Work with a reputable supplier who can meet your precision requirements.

- Cost and Lead Time: Consider both the short-term tooling investment and long-term production savings.

From automotive to aerospace, the demand for high-precision, cost-effective components ensures that metal stamped parts will remain a cornerstone of industrial production for years to come. Whether you're developing a new product or scaling up production, incorporating metal stamped elements can be a game-changer for your operations.