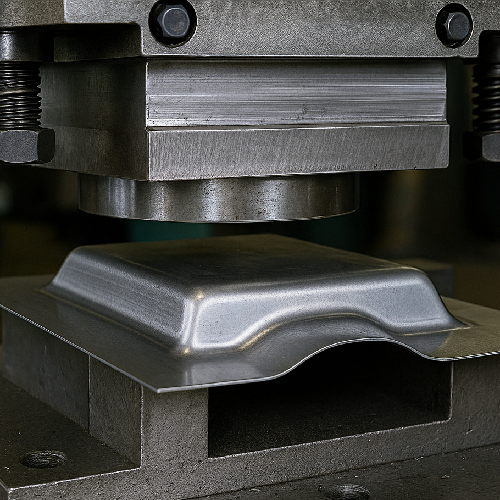

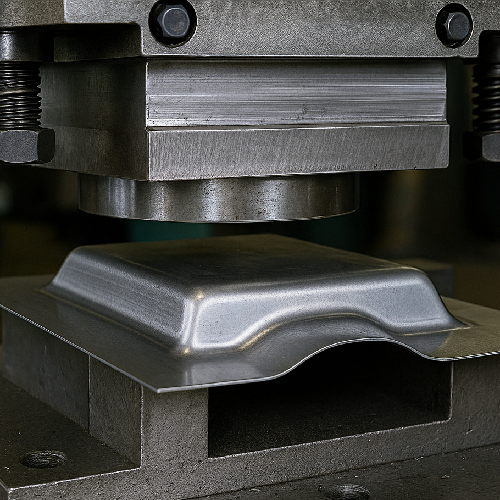

Metal stamping forming is a highly efficient manufacturing process used to convert flat metal sheets into specific shapes through the use of dies and stamping presses. This process plays a critical role in producing components for industries such as automotive, aerospace, electronics, and consumer appliances.

Key Components of the Metal Stamping Forming Process

1. Die and Tooling Design

- Dies are customized tools used to shape metal parts during the metal stamping forming process.

- Tooling includes punches and dies, which are essential for creating high-precision parts.

2. Stamping Press Types

- Mechanical presses are commonly used for high-speed applications.

- Hydraulic presses offer better control and are ideal for complex metal stamping forming tasks.

3. Material Selection

- Common materials include stainless steel, aluminum, copper, and brass.

- Material properties directly impact the efficiency and quality of the metal stamping forming process.

4. Blanking and Punching

- Blanking cuts the workpiece from the sheet, while punching removes unwanted material.

- These steps are typically the first phase of metal stamping forming.

5. Bending and Forming

- This phase shapes the blank into a three-dimensional form, utilizing techniques like air bending, bottoming, or coining.

- Accurate forming ensures part integrity and dimensional accuracy.

Advantages of Metal Stamping Forming

1. High Precision and Consistency

- Metal stamping forming produces parts with tight tolerances and repeatable accuracy.

- Ideal for mass production where consistency is key.

2. Cost-Effective for High Volumes

- Once the die is created, the per-part cost drops significantly.

- Suitable for long production runs with minimal material waste.

3. Speed and Efficiency

- Modern stamping presses can produce hundreds of parts per minute.

- Metal stamping forming dramatically reduces production cycle times.

4. Design Flexibility

- Complex geometries can be achieved with advanced die designs.

- Supports multi-functional parts in a single metal stamping forming step.

5. Material Optimization

- The process minimizes scrap and utilizes sheet metal efficiently.

- Lightweight and durable parts can be achieved with optimized material usage.

Common Applications of Metal Stamping Forming

1. Automotive Industry

- Chassis, brackets, and structural components are produced using metal stamping forming.

- Ensures high strength and safety for vehicle parts.

2. Aerospace Components

- Critical aerospace components require high strength-to-weight ratios.

- Metal stamping forming provides the precision needed for these parts.

3. Consumer Electronics

- Housings, connectors, and shielding components are manufactured through this process.

- Supports miniaturization and complex part requirements.

4. Medical Devices

- Metal stamping forming ensures clean, accurate parts for surgical tools and implants.

- Stainless steel and titanium are commonly used.

5. Home Appliances

- Covers, brackets, and panels in appliances rely on efficient forming methods.

- Aesthetic and functional parts are made to high standards.

Quality Control in Metal Stamping Forming

1. Inspection and Testing

- Dimensional checks, hardness testing, and visual inspections are routine.

- Ensures every part meets strict quality standards.

2. In-Process Monitoring

- Sensors and feedback systems detect anomalies in real-time.

- Helps prevent defective parts during the metal stamping forming cycle.

3. Tool Maintenance

- Regular maintenance ensures dies remain sharp and accurate.

- Extends tool life and maintains part quality.

Future Trends in Metal Stamping Forming

1. Automation and Robotics

- Robotic feeders and sorters enhance productivity.

- Automated systems reduce human error in metal stamping forming.

2. Smart Manufacturing Integration

- IoT-enabled machines provide real-time data for process optimization.

- Data analytics help improve efficiency and reduce downtime.

3. Advanced Materials

- Use of composites and high-strength alloys is increasing.

- Metal stamping forming adapts to these newer materials for superior performance.

4. Environmental Sustainability

- Improved waste management and energy-efficient presses support green manufacturing.

- Eco-friendly lubricants and recycling practices are becoming standard.