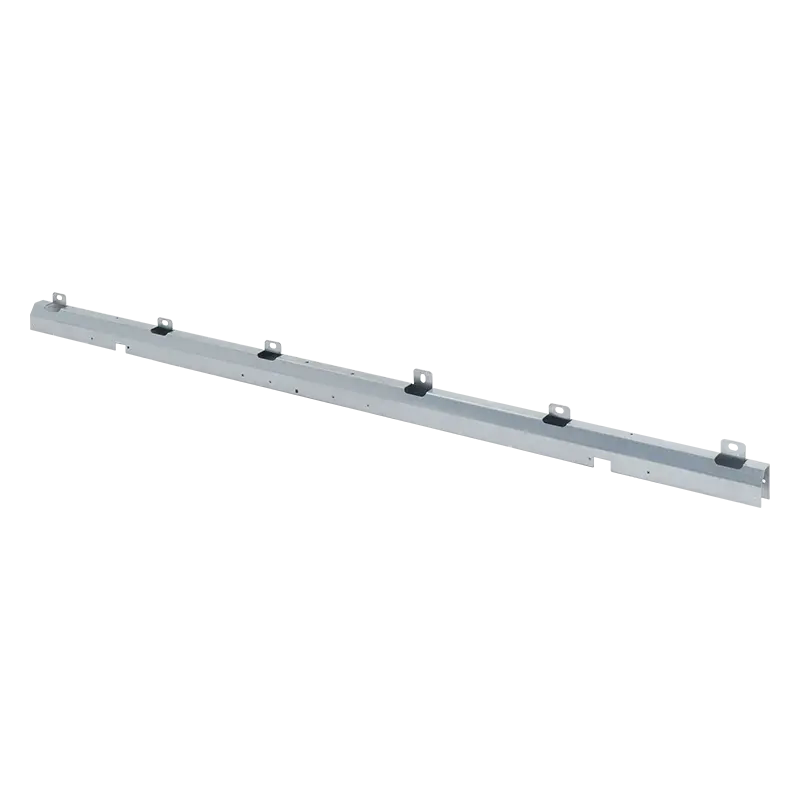

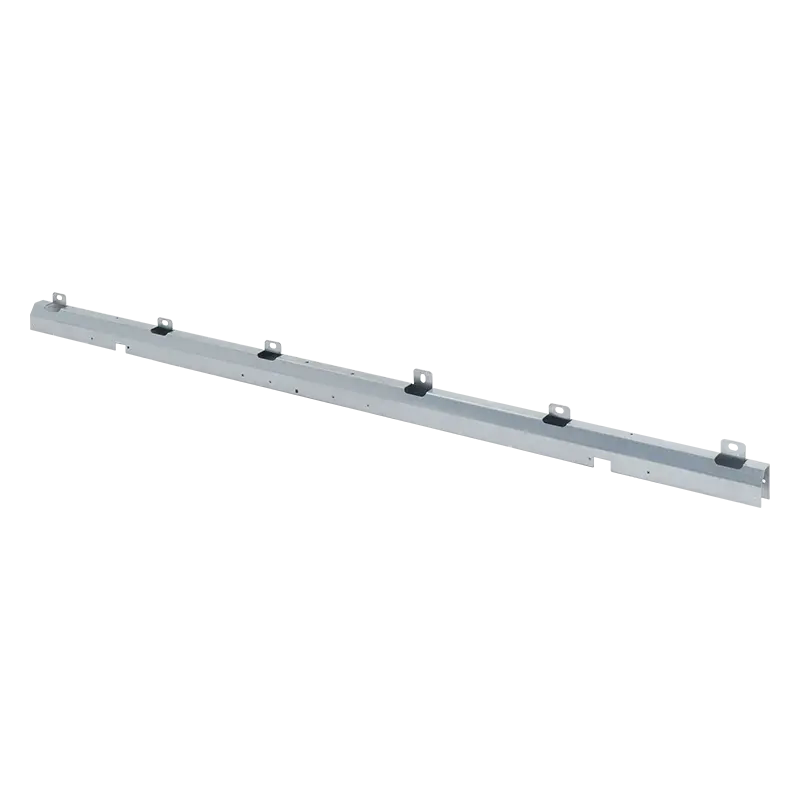

Metal stamped parts have become an essential component across numerous industries due to their precision, cost-efficiency, and versatility. These parts are created through a process known as metal stamping, where flat metal sheets are converted into specific shapes using dies and stamping presses. From the automotive sector to electronics and aerospace, metal stamped parts have significantly improved production speed and product consistency.

Advantages of Using Metal Stamped Parts

- High Precision and Consistency: Metal stamped parts are manufactured with tight tolerances, ensuring uniformity in large-scale production.

- Cost-Effective Production: The stamping process minimizes material waste and supports high-volume output, reducing overall manufacturing costs.

- Time Efficiency: With automated machinery and rapid cycle times, metal stamped parts can be produced at remarkable speeds.

- Durability and Strength: These parts often undergo heat treatment or surface finishing, enhancing their mechanical properties and resistance to wear.

- Design Flexibility: Metal stamped parts can be tailored to meet diverse specifications, including complex geometries and intricate details.

Common Applications of Metal Stamped Parts

- Automotive Industry: Components such as brackets, connectors, and body panels rely on metal stamped parts for structural integrity and precision.

- Electronics and Electrical Equipment: Contacts, terminals, and shielding components are often crafted as metal stamped parts due to their conductive properties.

- Aerospace Sector: The aerospace industry depends on lightweight, high-strength metal stamped parts for both structural and electronic systems.

- Medical Devices: Metal stamped parts are used in surgical instruments and diagnostic devices, where accuracy and cleanliness are paramount.

- Home Appliances: From washing machines to air conditioners, metal stamped parts are integrated into various internal mechanisms and housing components.

Key Materials Used in Metal Stamped Parts

- Aluminum: Lightweight and corrosion-resistant, commonly used in automotive and aerospace applications.

- Stainless Steel: Known for its strength and anti-corrosive properties, ideal for medical and food-grade equipment.

- Copper and Brass: Preferred in electrical applications for their excellent conductivity.

- Carbon Steel: Offers a balance of strength and affordability, making it a staple in general manufacturing.

How to Ensure Quality in Metal Stamped Parts

- Precision Tooling: Using high-quality dies and precision-cut tools ensures consistency in every stamped piece.

- Material Selection: Choosing the appropriate metal for the intended application improves performance and longevity.

- Regular Maintenance of Equipment: Well-maintained stamping presses reduce the risk of defects in metal stamped parts.

- In-Line Inspection Systems: Automated inspection tools detect anomalies in real-time, enhancing quality assurance.

Trends and Innovations in Metal Stamping Technology

- Progressive Die Stamping: This technique integrates multiple operations in a single pass, optimizing production efficiency.

- 3D Simulation and CAD Integration: Advanced software helps design more complex metal stamped parts with fewer iterations.

- Sustainability Practices: Recycling scrap materials and using energy-efficient machinery make the production of metal stamped parts more environmentally friendly.

- Micro Stamping: Catering to the miniaturization trend in electronics, micro stamping creates extremely small and precise components.